본문

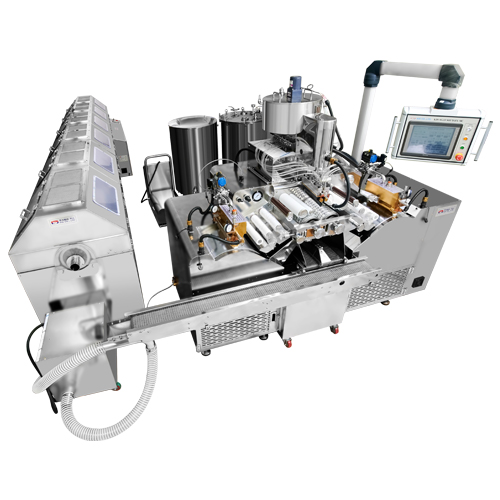

(JUMBO-DOUBLE INJECTION TYPE)

SOFTGEL ENCAPSULATION MACHINE

WITH TUMBLE DRYER SYSTEM

(For Mass-Production Application)

KIS-SG23JD SOFTGEL ENCAPSULATION MACHINE ADVANTAGE & FEATURE

1. Replaced by input of circumferential pocket quantity on touch screen without timing gear

2. When replacing the die, the die alignment can be accurately and easily aligned while viewing the die alignment with the micro-handle alone from the front (patent registered)

3. It is a method of inputting the medicine filling amount on the touch screen.

4. You can see the medicine filling time with your eyes and set it exactly at the desired time.

5. The timing of medicine filling can be arbitrarily changed during production. (Numerical control method)

6. The amount of ribbon oil supply is adjusted by input on the touch screen.

7. Separately supply the inside and outside of the ribbon oil

8. DIE Size: ф150 X 290Lmm

Specification

Working speed: Approx. 2-5 rpm

Production is possible to control viscosity of injecting fluid

Display gelatin sheet thickness automatically

Electronic control system of Die Roll setting (Air Cylinder)

Electronic control system of injection time adjustment.

Automatic air blower type for capsule carrying into the Tumble Dryer

Quantity of plunger: 20pcs / Size of Cooling Drum: f500x280mm

Size of Die Roll: f150x290mm (Customer have to select Capsule shape & size)

Main motor: 2 HP (1.5KW) with speed controller

Air cooling Chiller x 1set : Power consumption 6.5 kW

Total power consumption: Approx 24kW

Voltage: 380V, 3 phases / Frequency: 50 or 60Hz

Weight: Approx 2,000 kg / Dimension: 990mmW X 2,180mmL X 1,975mmH