본문

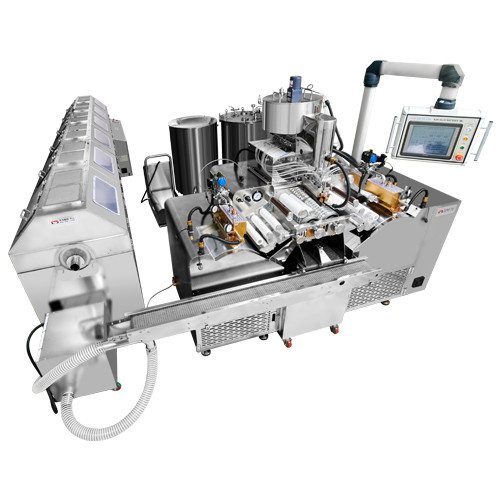

SOFTGEL ENCAPSULATION MACHINE

WITH TUMBLE DRYER SYSTEM

(CE Certificate)

Consist of Basic machine with included::

-Equipped PLC & Touch screen HMI Control system

-Included Capsule conveyor & Blower to convey capsule into tumble-dryer.

-Servo control fill medicine amount regulation value input to the Touch screen

(No need timing Gear)

-Included a set of Die-roll

-Equipped Die alignment devices controlled by a stepping motor (Patent)

-Equipped casting drum air blower (rpm control)

-Included an Air-cooled auto-chiller (HD-02A) 6.5kW

-Equipped Vegetable Spreader Box: R, L 1set

-Included Gear pump & Heating hose for Vegetable capsule process

-Instruction manual (English version)

Specification

Working speed: Approx. 2-5 rpm

Production is possible to control viscosity of injecting fluid

Display gelatin sheet thickness automatically

Electronic control system of Die Roll setting (Air Cylinder)

Electronic control system of injection time adjustment.

Automatic air blower type for capsule carrying into the Tumble Dryer

Quantity of plunger: 20pcs / Size of Cooling Drum: f500x280mm

Size of Die Roll: f150x290mm (Customer have to select Capsule shape & size)

Main motor: 2 HP (1.5KW) with speed controller

Air cooling Chiller x 1set : Power consumption 6.5 kW

Total power consumption: Approx 24kW

Voltage: 380V, 3 phases / Frequency: 50 or 60Hz

Weight: Approx 2,000 kg / Dimension: 990mmW X 2,180mmL X 1,975mmH